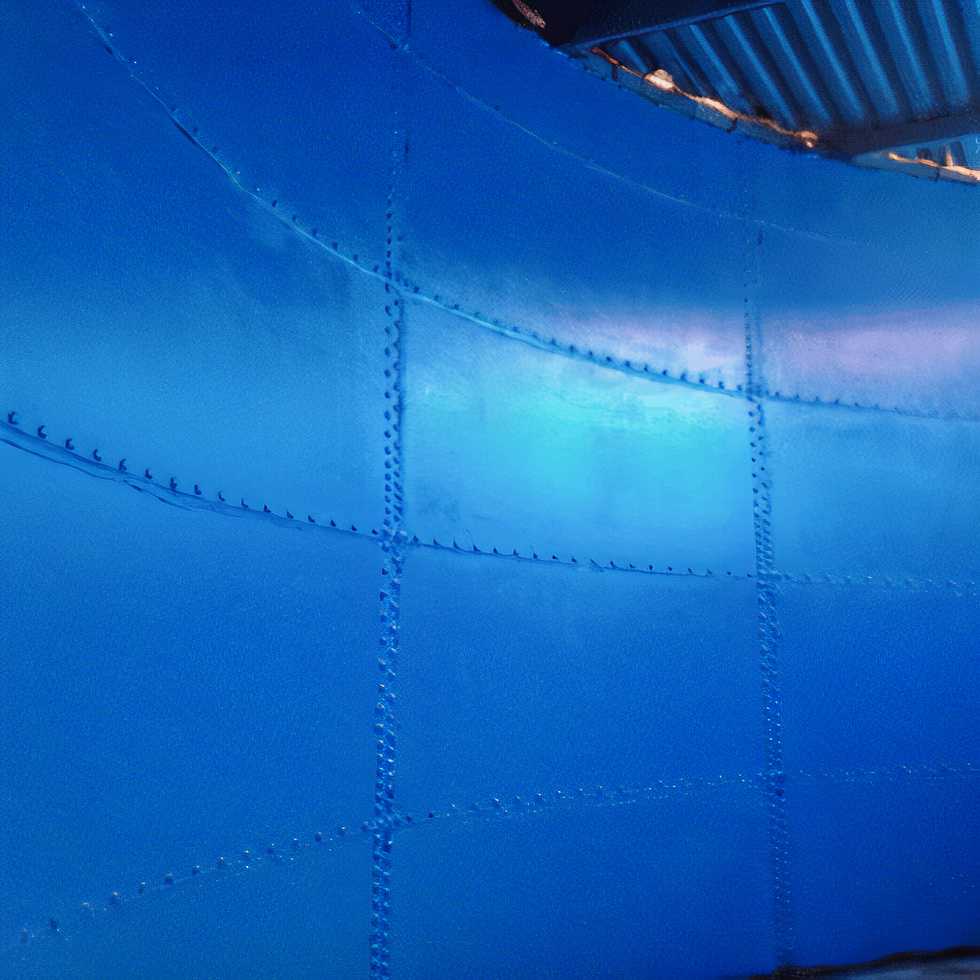

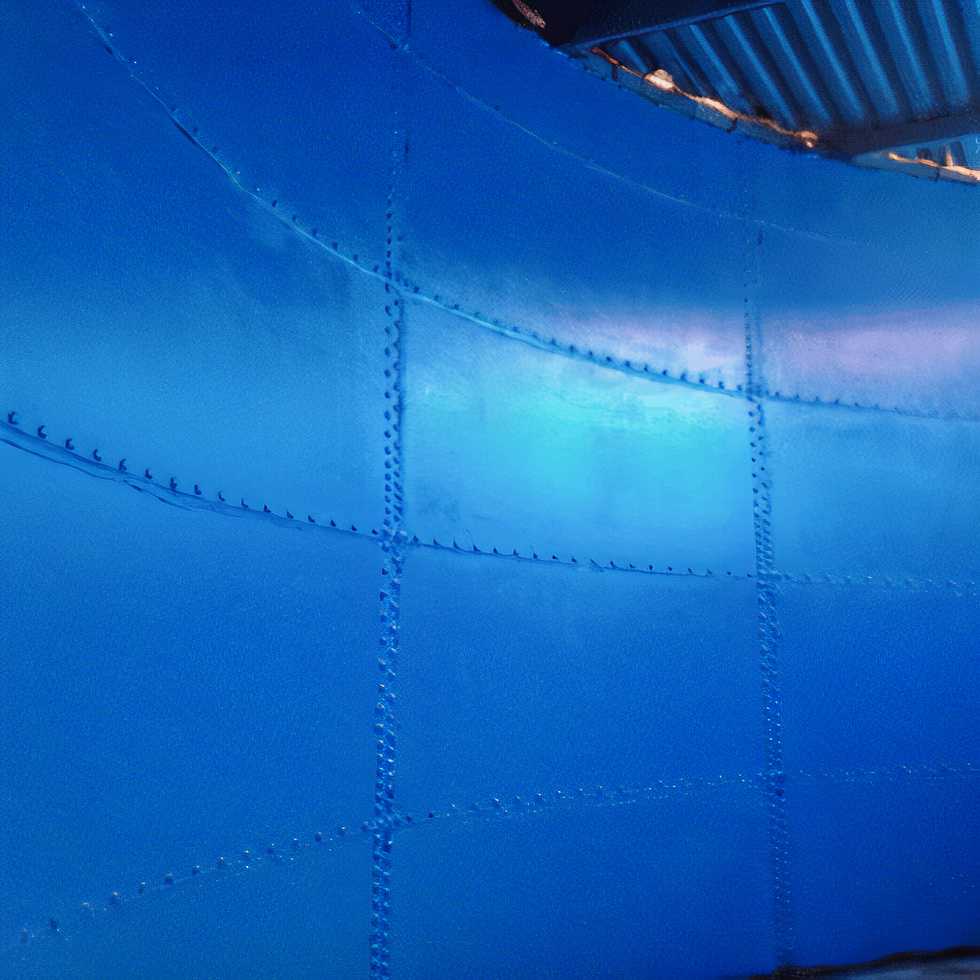

Epoxy Tank Coating and Lining

We have experience working on a wide range of Epoxy Tank Coating and Lining systems that are designed for a variety of industries and settings.

However, we believe that our service offers the quality and efficiency that sets us apart. We provide an Epoxy Tank Coating and Lining service that meets your specific needs and we also offer a range of different finishes in a variety of colours too.

While our coating system is surface tolerant, it is also suitable for grit-blasted surfaces and for covering over areas that have been previously repaired.

While grit blasting is not always required, we make sure that those surfaces that will be covered are free of oil, grease, residue and particles.

GALLERY

Extensive Epoxy Tank Coating and Lining Experience

Our service comes backed with our experience of working on a wide range of projects that include fuel tanks, process tanks, large holding tanks and sprinkler tanks. This means that we have a lot of experience and expertise that allows us to provide a professional service and finish every time.

We have a wide selection of epoxy coatings available that are suitable for almost every application including vapour curing, acid-resistant, industrial floor and extreme temperature epoxies.

Certified Epoxy Tank Lining and coating Experts

We are fully certified as the work that we do uses epoxy tank coating and lining systems that are DWI/WRC certified, and this makes them suitable for use with potable water applications. So, it enables us to utilise these solutions for use across both domestic and commercial settings.

When we undertake epoxy tank coating and lining, we recommend that submerged surfaces should have a minimum of two coats applied as this will help to enhance protection.

Our external products have a minimum temperature limitation of 5 degrees celsius and any temperature below this will lead to a reduction in the curing process.

However, we also have a selection of Polyurethane coatings that carry the same properties but the temperature threshold is lower.

epoxy tank coating and lining Details

What makes epoxy such a useful solution is that it is versatile and can be used across a range of applications.

It can also be solvent-free which can help to reduce VOC emissions while it protects against corrosion in those environments that are considered aggressive and are susceptible to high temperatures.

Get in touch to learn more about our range of epoxy tank coating and lining services.

Uses of epoxy tank coating and lining

Epoxy can be used in a number of applications and this can include steel tanks and even cargo tank linings where protection is required against chemicals, oils, wastewater and high-temperature crude oil.

Therefore, you can rely on our service for the following applications:

Sectional steel tanks

Fuel tanks

Concrete tanks

Potable water tanks

Sprinkler tanks

For quality assurance and application carried out correctly, it’s advised that you use reliable, trained and experienced professionals to handle your tank lining requirements. If the coating is applied incorrectly, then the coating could fail and that could lead to further costs to rectify the problem. Our service ensures that you can benefit from epoxy tank coating and lining that ensures your tank is protected and lasts.