Industrial and Process Tank Linings

Process tanks are generally concealed and out of sight, which means that problems can arise without being recognised early enough. So, over a period of time, the tank and the structure can deteriorate and when this occurs, the issue is more often than not linked to corrosion or tank perforations.

While this might not initially sound serious, it is a problem that could lead to contamination or a spill that could prove dangerous.

Industrial Process tanks and systems are growing in popularity and we are not carrying out work on more of them and so, we have seen first-hand, the range of problems and the outcome of not dealing with issues soon enough.

This system is growing in popularity due to environmental policy and water conservation. So, if you want to ensure that your system is safe and reliable, we have an industrial and process tank lining that can protect against acid and alkalis.

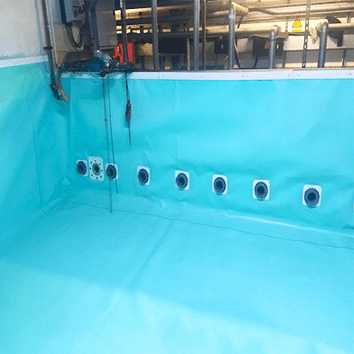

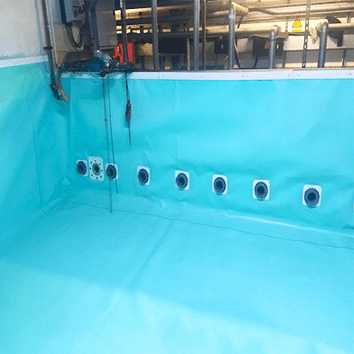

GALLERY

If you are looking to save time and money, then tank refurbishment is often the best choice, especially when compared with a full replacement. Often, access to tanks is difficult but our flexible system is designed for process tank lining and refurbishments, ensuring that it is suitable for most tanks.

Essentially, if we can get into the thank, then we can line it.

The industrial and process tank linings that we offer are flexible and environmentally friendly while they offer high-level durability. As the system can be installed quickly, it is ideal for tank refurbishment projects.

When process tanks are taken out of use, it often means that production or other processes are disrupted, so it’s especially important to make sure that the work is completed quickly and efficiently.

Our system is manufactured off-site and is then transported to the location and this helps to speed up the time we have to spend on location.

This means that industrial and process tank linings can be installed in just a few hours.

Durable industrial and process tank linings for a Range of Conditions

Opting for a refurbishment can save you 80% on the cost of a replacement. If your tanks are looking worn and are showing signs of damage, there is no need to replace them. As our industrial and process tank linings system can cost as little as 20% of the cost of a replacement, it makes it a cost-effective solution.

Our lining system is hard-wearing and can be designed to handle a range of conditions and contents as they can be customised by using a range of resins and additives.

Whether it’s a water tank, chemical water tank or other types of tanks, we have the scope to line your tank and reduce downtime and costs.

Our range of solutions are designed to help you avoid the need to replace your tanks. We have the expertise, knowledge and experience to fix most problems rapidly and efficiently.

Through our precision and professional approach, we have the scope to identify the right solution before completing all works, ensuring your tanks can be put back into action once again.

Applications for industrial and process tank linings

Acid Cleaning

Cooling Water Systems

Electroplating Companies

Zinc Plating Companies

Get in touch today to learn more about our industrial and process tank linings system.