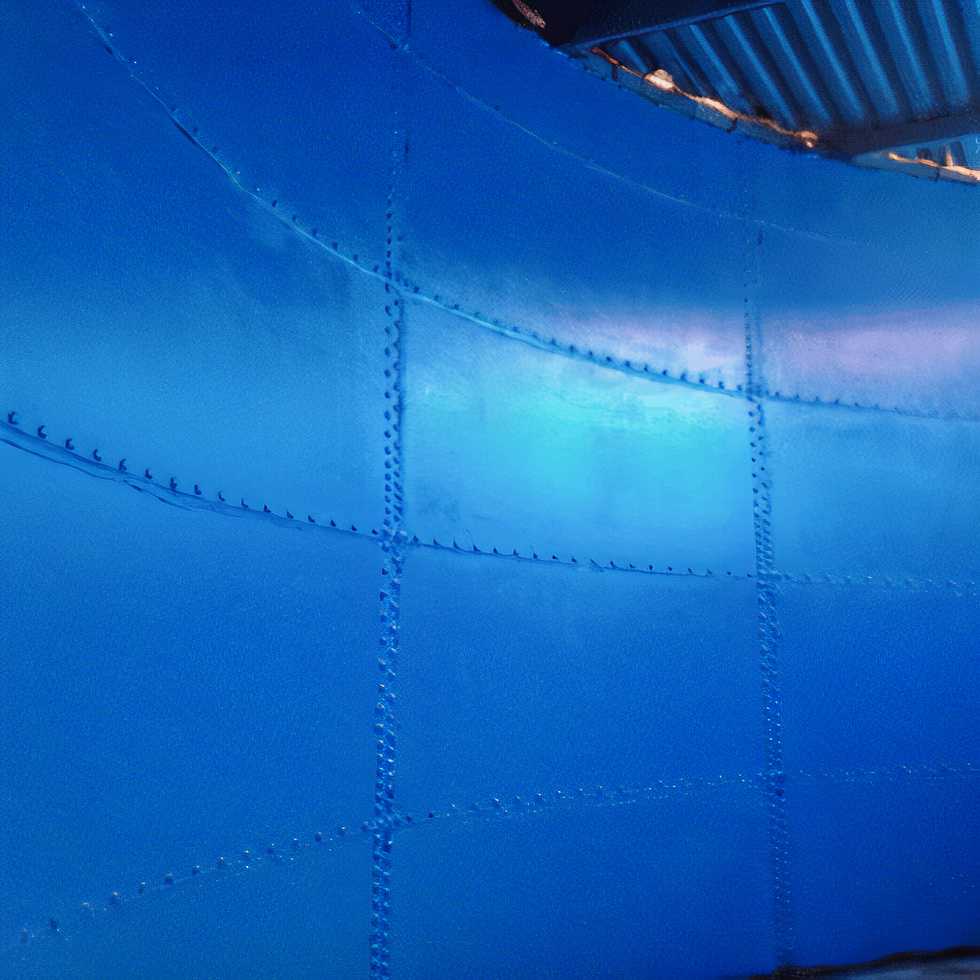

Sprinkler Tank Epoxy Repair System

Existing sprinkler tanks can suffer from damage and deterioration over time. When this occurs, there’s no requirement to replace your tank as we can provide sprinkler tank epoxy repair.

Our Sprinkler Tank Epoxy Repair System is designed to help you save money and ensure that your tank is fit for purpose.

This service involves undertaking a physical repair of current tank perforations before applying a corrosion-resistant coating that can help to reduce further corrosion and prevent leaks.

This repair system is a popular choice and is one that we have applied to a wide range of projects although we will assess your tank to ensure that we carry out the correct solution.

GALLERY

What is the Sprinkler Tank Epoxy Repair System process?

Our engineers will arrive on site and begin all preparatory work, which involves closing and tagging the sprinkler tank inlet valve.

We then isolate the system and carry out electrical tagging of all power supplies and pumps. At this point, we can then begin the process of draining your tank and we do this slowly over a period of 24 to 36 hours as this enables us to avoid problems such as flooring and backing up.

Once drainage has taken place, we then place confined space and ventilation equipment into the area where access will be made.

We complete all checks on permits and method statements while we use submersible pumps to remove any remaining water, silt or sediment.

To ensure we complete a perfect job, we prepare the internal surface using blade scrapers and brushing before finishing with 3600psi jetting.

Sprinkler Tank Repair System

We then begin the process of carrying out our sprinkler epoxy coating system. This involves using a three coat epoxy paint system that helps to protect the tank and enhance its lifespan.

Our specialists undertake the entire job with accuracy and precision, ensuring they do everything right and meet our high standards. They also place a focus on safety and make sure that they adhere to all health and safety regulations.

Our Sprinkler Tank Epoxy Repair System

This service is required where corrosion is severe and in some instances, we may be required to use grit blasting.

The epoxy coating system that we use is known as a Surface Tolerant Coating and this can be applied to any surface. Once the surface has been prepared, all leak areas and damaged areas will be easier to identify. We then carry out all necessary fibreglass repairs to ensure that these areas no longer pose a threat.

We then apply a brush sealing compound to the area and this is applied to the section where the wall meets the concrete base of the tank. This helps to enhance the lifespan of the original seal and ensures that it remains watertight.

We then apply our three coat epoxy system that is applied to the tank walls and roof supports. This helps to eliminate any potential corrosion in the future and finishes the tank repair work.

We then leave the tank for a further 24 hours to help finish the epoxy curing process. The tank is then refilled over a period of 12 hours before all pumps and valves are reinstated.

This process usually takes around 7 days to complete and this ensures that the entire process is completed professionally and correctly.